Rail Door and Step Solutions

We have delivered innovation and performance to the rail door market since 1987. We currently have over 17,000 interior door systems, and more than 24,000 exterior door actuation and control systems, installed on rail cars all over the world - from Siemens’ Desiro and ICE fleets to Shanghai’s Transrapid Maglev train.

We design customised door actuation and control solutions with the quality assurance we know the rail industry demands:

- Temperatures ranging from -40°C to +80°C

- Environment humidity: 95%

- System life time: >30 years

- Shock and Vibration: EN 61373

- Fire and smoke: DIN 5510, NF F16-101, EN 45545

- Voltage: 24 to 110 VDC +/- 30%

- Door closing time: 4 sec

- Door opening time: 2 sec

External door systems

- Special pneumatic/electric actuation and control system

- Safe, reliable and secure operation

- Interlocking and feedback drive systems

- Extended cushioning and increased side load stability

- Entrapment protection

- Many years of proven reliability and safety in Metro, EMU and HST applications globally

Internal door systems

- Special manual, pneumatic and electric actuation, with integrated control system

- Safe, reliable and secure operation

- Interlocking and feedback drive systems

- Fire and smoke compliant

- Entrapment protection

- Smooth, quite design with variable speed drive

- Solutions for new and existing train carriages to reliably fit into the same space as the previous design

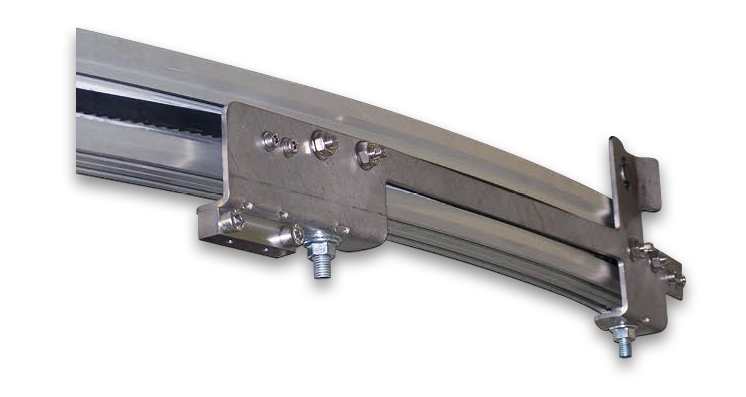

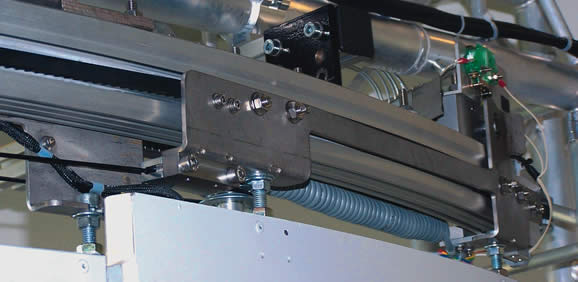

Curved door systems

- Electric and pneumatic curved actuator system

- Curved guiding profile

- Maximises limited space with telescopic, syncronised opening

- Field serviceable design

- Locking system and emergency access override

- Robust guiding, low maintenance costs and easy replacement

- Meets TSI PRM 2008/164/EC legislative requirements for disabled access

Door control valve systems

- Modular valve assemblies

- Easy replacement of existing systems

- Quick installation and maintenance

- Reduction in downtime

- Custom designs to suit specifications

Case Study - Curved Doors

A national train operating company needed to modernise their existing toilet door solution to ensure they complied with PRM TSI 2008/164/EC legislation regarding disabled access.

We developed an innovative curved actuation solution that provided syncronised, telescopic door operation, either electrically or pneumatically. The solution incorporated a locking system and emergency access override, and complied with all standard rail door specifications including obstacle detection.

The result was an increased aperture when the doors were opened, allowing improved wheelchair access, with push-button operation making it easier for passengers. The application-specific solution fully met the needs of the customer, and ensured compliance with all current and future legislation regarding disabled access.

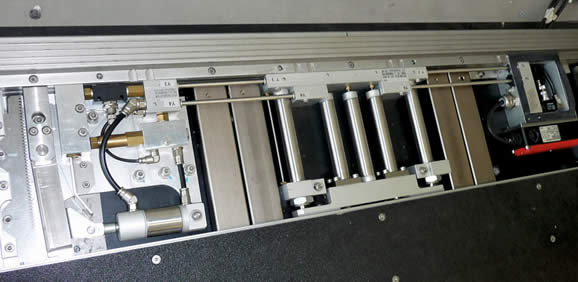

Case Study - Step Control

An underground train operator faced the problem of an excessive gap between the train door and the platform, which created a safety risk for passengers. In addition, the gap between the doors and the platform was not consistent, and varied between stations.

The customer required a variable step which would fit the gap at any station. The solution also needed to fit within a very restricted space beneath the existing door system.

Our engineers developed a range of cushioned, telescopic cylinders that could be mounted below the existing door system. By applying a set pressure, this cylinder system would fill the gap between the train and the platform, regardless of the size of the gap.

Due to the strict envelope size, our solution used only 50% of the space of a traditional step system. It included all the required standard safety features, including obstacle detection and could be integrated into the existing door control system.