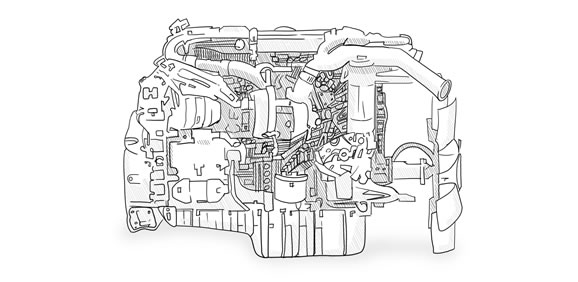

Engine Solutions

Our solutions meet the challenging temperature and vibration requirements of today’s heavy duty trucks and off-highway engines. We have developed a core set of technologies to assist with systems such as EGR, SCR, enhanced waste-gate and diesel particulate filtration.

We provide high-performance pneumatic and electric control using innovative valve and actuation technology for all current and future engine control requirements.

Inlet throttles

This high-performance product provides EGR assistance, maintains elevated exhaust temperature and enables rapid engine shutdown:

- High-durability brushless DC actuator

- Pipe-mounted, die-cast aluminium housing

- Stainless steel flap and shaft

- CAN J1939 smart actuator, 12V and 24V

- Safety spring return to normally open

- Compact direct drive

Variable-geometry turbocharger control

We offer high-performance, advanced pneumatic control for Variable Geometry Turbochargers (VGT) – a fully integrated closed loop control system that includes an ECU, pressure sensor and a proportional valve:

- Communication with the engine and/or the vehicle ECU is possible

- Available with pressure or displacement feedback, and with PWM or CAN control

- Suitable for use with Euro IV, V, VI, EPA requirements, or Tier 4 final applications

- IP6K9K-rated enclosures

Engine control multi-function valve block

This high-performance product integrates two waste gates for two-stage turbo and exhaust brake functions into one module:

- Integrated pressure regulator and exhaust back pressure sensor

- Utilises production-proven solenoids

- Reduces total cost of ownership

- Single air connection, single electrical connection

EGR control

Our customised EGR solutions provide precise pneumatic proportional control for ‘hot side’ EGR valves:

- Proven product with years of medium and heavy-duty diesel engine usage

- Suitable for EPA requirements, Tier 4 Final and Euro IV, V and VI solutions

Case Studies

Discover how our powertrain engine solutions help commercial vehicle manufacturers satisfy emissions legislation.

Engine exhaust brake control

Fully proportional control of exhaust brake with integrated exhaust back pressure sensor provides savings in weight, footprint and component count:

- Precise pneumatic control of the exhaust brake

- Directly driven, improving response speed by approximately 30%

- Single standard mounting needed for installation

- Durable design capable of surviving under-hood temperatures and vibration environments

SCR system ad-blue tank heating

Utilising engine coolant circuit for medium and heavy duty truck engines, the Urea Tank Heating Valve (UTHV) regulates the flow of coolant to the Ad-Blue / urea holding tank:

- Poka-yoke application-specific fittings allow for easy installation

- Regulates temperature in cold ambient environments, protecting it against freezing

- Reducing unit weight by 200g, it delivers more efficient fuel consumption

- Effective on or off highway, it performs with all engine applications

- Designed specifically for colder operating conditions, it ensures uninterrupted operation

- Use of high-performance materials minimises maintenance

Motorised valves

Our range of Buschjost motorised valves are used to control coolant fluid in battery circuits to improve the performance, reliability and efficiency of thermal management systems on board hybrid, electric and fuel cell vehicles.

- Minimum hysteresis proportional control

- Chemically compatible with a number of coolants

- Low power consumption

- More information